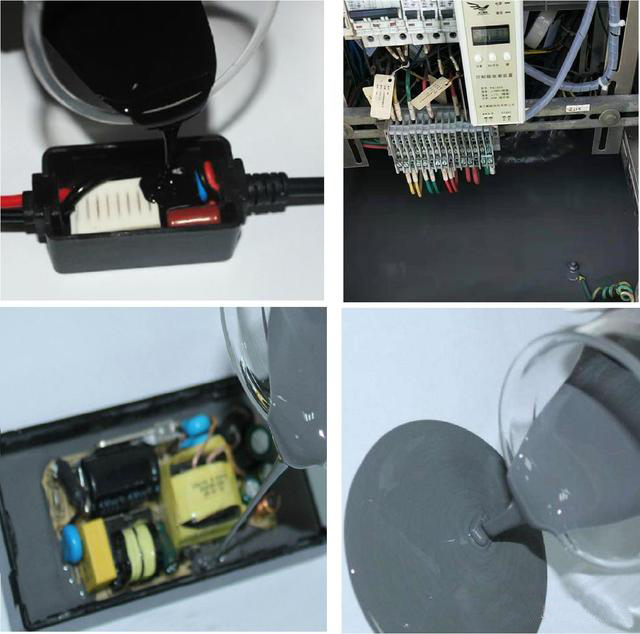

Vertical comparison of performance of potting compound

AYAAON provides three types of thermal conductive potting materials, they can be divided into:

1. Epoxy resin heat conductive potting: two components epoxy resin potting adhesive;

2. Silicone resin heat conduction potting compound: room temperature vulcanized silicone rubber, two-component addition cure silicone rubber potting compound, two-component condensation cure silicone rubber potting compound;

3. Polyurethane heat conduction potting: two-component polyurethane potting;

![]()

Now, how too choose? What's the difference between these thermal conductive potting materials? Let AYAAON share the vertical comparison of performance of potting compound:

1. Cost: silicone resin > epoxy resin > polyurethane;

Note: In silicone resin, the cost of condensation type is close to that of epoxy resin, and the modified epoxy resin is close to that of PU;

2. Processability: epoxy resin > silicone resin > polyurethane;

Note: Due to the hydrophilicity of PU, vacuum drying is necessary to obtain better solidified products. If vacuum and drying are not required, the cost is too high. Therefore, although the thermosol is heated, dissolved and poured, its operability is much simpler than that of PU in general;

3. Electrical performance: epoxy resin > silicone resin > polyurethane;

Note: Some electrical properties of the addition cure silicone or paraffin type hot-melt adhesives are even higher than those of epoxy, such as surface resistivity;

4. Heat resistance: silicone resin > epoxy resin > polyurethane;

Note: The heat resistance specific heat sol of PU with low price is not much better;

5. Cold resistance: silicone resin > polyurethane > epoxy resin;