Macromolecule polymer for ring network cabinet encapsulating

- Product Usage:Macromolecule potting polymer is suitable for outdoor 10kV High and low voltage switch cabinet, box type transformer cabinet, cable branch box, ring main cabinet, common box type ring main cabinet, circuit breaker cabinet, full insulation expensive, 10kV outdoor switching station, distribution network control cabinet, GGD incoming and outgoing line switch cabinet terminal box, xl-21 power cabinet, wind box transformer, photovoltaic box transformer, PLC control box, high-speed railway box transformer, mercury control box and its power equipment, cable inlet and outlet and cabinet bottom waterproof, dust-proof, heat insulation, flame retardant, heat insulation, Sealing effect of anti condensation

Description

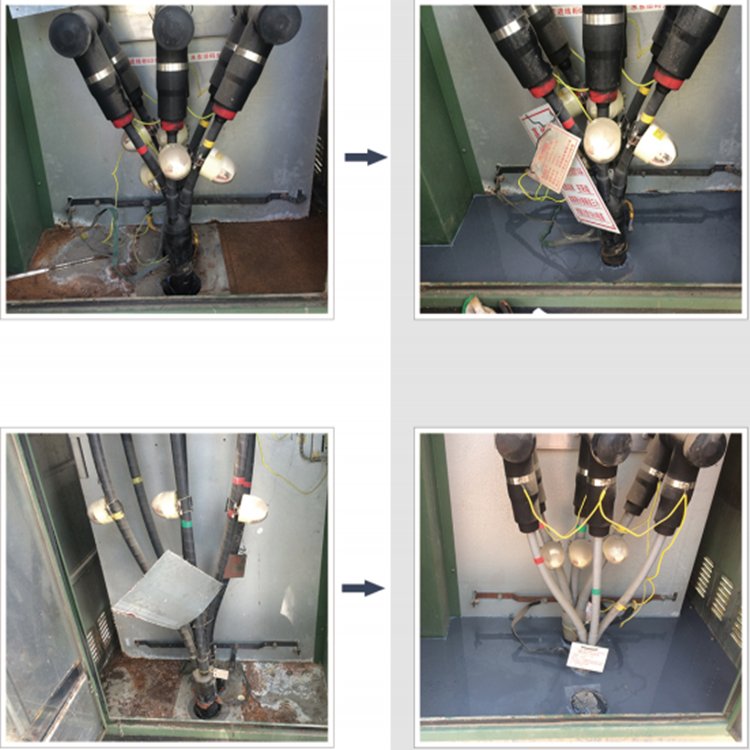

APPLICATION OF MACROMOLECULE POLYMER ON THE FLOOR OF ELECTRICAL CONTROL CABINET

Macromolecule potting polymer is suitable for outdoor 10kV High and low voltage switch cabinet, box type transformer cabinet, cable branch box, ring main cabinet, common box type ring main cabinet, circuit breaker cabinet, full insulation expensive, 10kV outdoor switching station, distribution network control cabinet, GGD incoming and outgoing line switch cabinet terminal box, xl-21 power cabinet, wind box transformer, photovoltaic box transformer, PLC control box, high-speed railway box transformer, mercury control box and its power equipment, cable inlet and outlet and cabinet bottom waterproof, dust-proof, heat insulation, flame retardant, heat insulation, Sealing effect of anti condensation

PROSPECT OF MACROMOLECULE POLYMER FOR RING NETWORK CABINET ENCAPSULATING

With the rapid development of the domestic economy, the electricity consumption of residential quarters, industrial zones and enterprises has increased very fast, especially in the main urban living areas and concentrated areas of industrial parks.

The degree of power load is high, and the safety is particularly important. The development and application of distribution network dominated by ring main cabinet can improve the stability and continuity of power supply and prevent the impact of power failure and power outage. But most of the ring main cabinets are installed outdoors, which is greatly affected by the environment. It is easy for moisture to enter the cabinet through the cable trench at the bottom of the ring main cabinet. The environment with high and low temperature difference and humidity temperature will produce condensation, which will rust the internal equipment fault display, electrical indicators and operating mechanisms, corrode the cabinet low and bottom plates, increase maintenance costs and reduce the service life of the ring main cabinet. The sealing materials of the cable trench and the ring main cabinet are particularly critical. The high molecular dampproof plugging agent can effectively solve the problem of caulking, plugging and sealing between the ring main unit and the cable trench because of its characteristics of flame retardancy, fire prevention, heat insulation, waterproof, moisture-proof, dust-proof, corrosion-resistant and anti-aging.

OPERATION OF FOR RING NETWORK CABINET ENCAPSULATING

1. Weigh the weight ratio of component A and component B according to the correct mix ratio (weight ratio) is measured correctly. If there is a large error in the measurement of the mixing ratio, the characteristics of the product will not be displayed well.

2. Mix and stir evenly part A and B

Mix and stir component A and component B evenly. When glue A and B are mixed, pour the part with a small proportion into the part with a large proportion. When mixing, stir in one direction. Do not stir too fast for about 3 minutes. Stir the bottom and wall of the container evenly. If it is not stirred evenly, curing will not occur in the later stage. The core of the mixing container must be about 3 times of the mixing compound.

3. Vacuumize and exhaust bubbles

After stirring evenly, move it to the vacuum box to enter the ground for defoaming. The bubbles involved during mixing will raise the liquid level, and the liquid level will drop again after the bubbles break. The degree of vacuum and the time of vacuuming depend on the viscosity of the glue and the requirements of the product (the defoaming time is generally 2-4 minutes). If there is no straight air machine, it can be stirred clockwise for 2-3 minutes. After stirring evenly, the glue can be placed on the fishnet for 5-20 minutes to automatically defoaming.

4. Pour in potting adhesive and wait for curing

Inject the necessary amount of glue, and pay attention not to get involved in bubbles. After flowing into the bottom along the inner wall of the shell, let the glue level rise slowly to avoid covering the air inside. After injection, it is cured at a predetermined temperature.