UL94V-0 flame retardant electronic potting compound

- Product Usage:The electronic potting adhesive can be mainly divided into epoxy resin potting compound, silicone potting compound and polyurethane potting compound.

Description

FUNCTIONS OF UL 94V0 FLAME RETARDANT ELECTRONIC POTTING COMPOUND

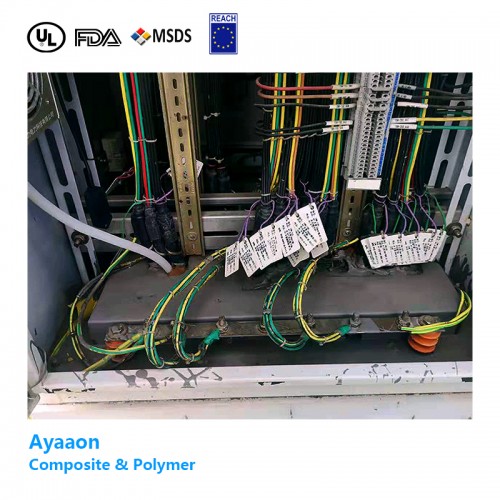

Strengthen the integrity of electronic devices and improve the resistance to external shocks and vibrations; Improve the insulation between internal components and lines, which is conducive to the miniaturization and lightweight of devices; Avoid direct exposure of components and circuits, and improve the waterproof and moisture-proof performance of components.

CLASSIFICATION OF UL 94V0 FLAME RETARDANT ELECTRONIC POTTING COMPOUND

Electronic potting compounds are widely used, and various electronic components have different requirements for them. In order to meet customer needs, businesses have developed various electronic potting compound, resulting in a wide variety of electronic potting adhesives.

The electronic potting adhesive can be mainly divided into epoxy resin potting compound, silicone potting compound and polyurethane potting compound.

1. The silicone heat conductive potting compound is a low viscosity flame retardant two-component liquid material, which can be cured at room temperature or by heating. It is characterized by faster curing with higher temperature. There are many kinds of silicone potting adhesives. Different kinds of silicone potting have great differences in temperature resistance, water resistance, insulation, optical properties, adhesion to different materials, soft and hard properties.

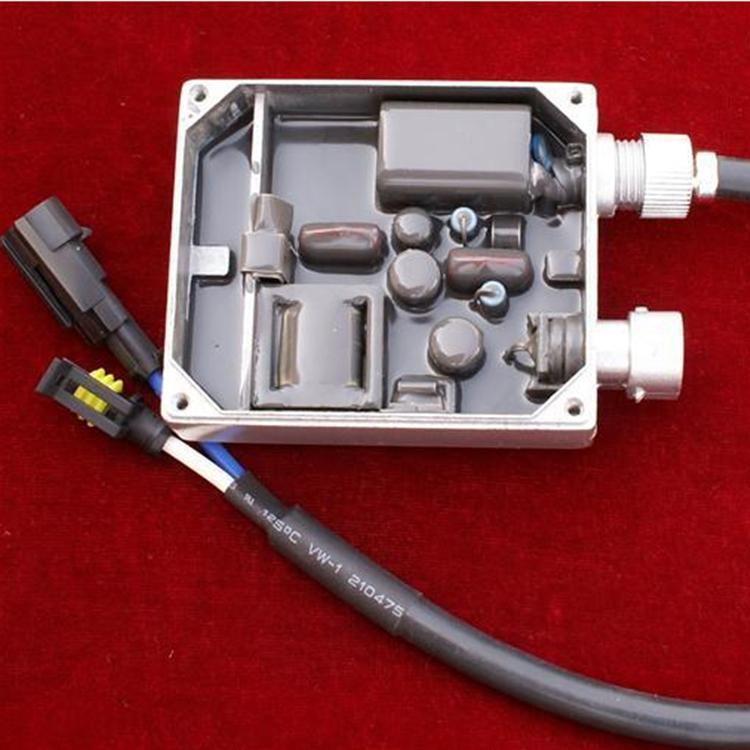

2. The epoxy resin potting compound has passed the European Union ROHS designated standard. The cured product has high hardness, smooth surface, good luster, and is characterized by fixation, insulation, waterproof, oil proof, dust-proof, anti-theft seal, corrosion resistance, aging resistance, cold and hot shock resistance, etc.

3. Polyurethane potting materials are characterized by moderate strength, good elasticity, water resistance, mold resistance, shock resistance, transparency, excellent electrical insulation and flame resistance, no corrosion to electrical components, and good adhesion to steel, aluminum, copper, tin and other metals, as well as rubber, plastic, wood and other materials.