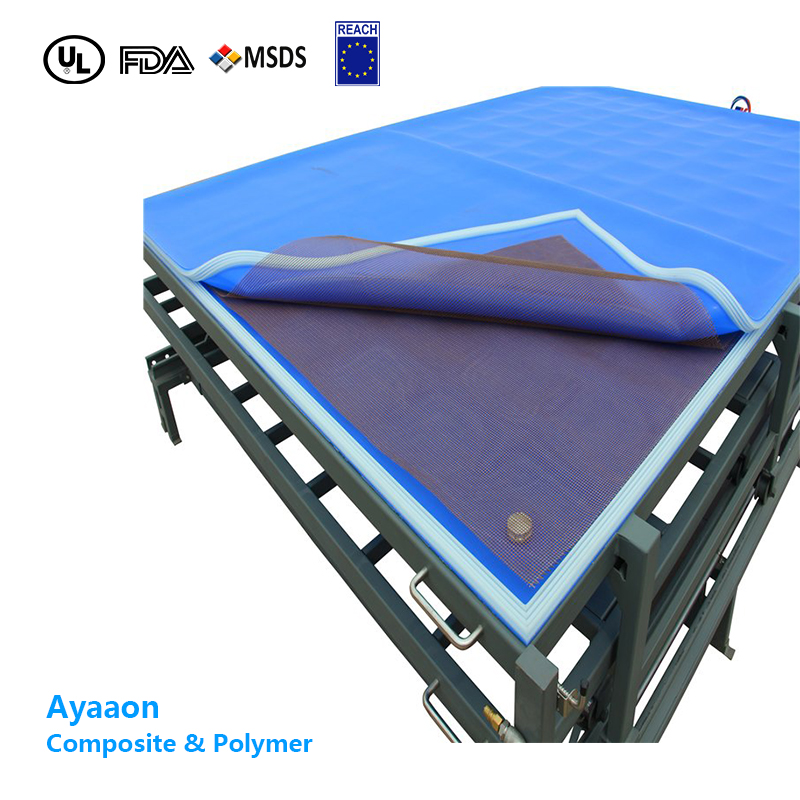

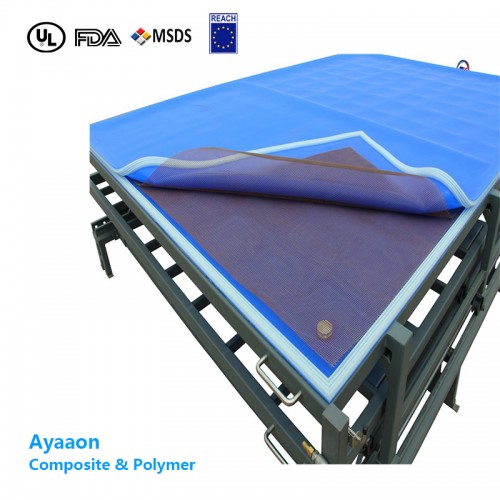

Epoxy resin for vacuum bag

- Product Usage:The raw material of epoxy resin for vacuum bag is suitable for wind power blade, engine hood, yacht, auto parts, machinery, building materials, carbon fiber, aerospace and other large component composite materials

Description

General properties: Special epoxy resin for vacuum bagging is a high-performance composite vacuum filling (VIP process) epoxy resin modified by carbon nanotube reinforcement technology patent.

Application: The raw material of epoxy resin for vacuum bag is suitable for wind power blade, engine hood, yacht, auto parts, machinery, building materials, carbon fiber, aerospace and other large component composite materials

Composition information:

Glycidyl ether 60% - 90%,

Other non hazardous components 40% - 10%

Physical and chemical properties

Physical state: liquid

Hue: light black

Smell: slight smell

Solubility: slightly soluble in water

TECHNICAL DATASHEET

Resin system

Resin viscosity (25 ℃): 1300mPas

Density: 1.13-1.16g/cm3

Flash point: 230 ℃

Curing agent

Viscosity (25 ℃): 19mPas

Density: 0.9-1.0g/cm3

Flash point: > 200 ℃

Mixing characteristic

Weight ratio: epoxy resin : curing agent: = 100 : 30

Gel time min (25 ℃) 90

Glass transition temperature (℃) 80

Mechanical properties:

Curing method: curing at room temperature, and treatment after 3 hours at 50 ℃

Performance of liquid state:

Tensile strength: ≥ 63MPa

Tensile modulus: ≥ 2.9GPa

Tensile fracture strain: ≥ 4.0%

Bending property (ISO 178) Bending modulus: ≥ 2.9GPa

Bending strength: ≥ 105MPa

Composite material performance (glass fiber uniaxial UD1200)

Tensile strength: ≥ 930Mpa

Tensile modulus: ≥ 44Gpa

Compressive strength: ≥ 630Mpa

Compression modulus: ≥ 42Gpa

Operation information

1. Before mixing: remove dust, grease and moisture from the mold surface

2. Mixing: Mix the resin and curing agent in proportion and leave for 2-5 minutes to let the bubbles escape. It can also be operated in a vacuum environment

3. Curing process: the product is cured at 25 ℃, and treated after 3 hours at 50 ℃

Storage conditions

The resin system will not crystallize when properly stored in a closed container, and should be stored in a closed container to avoid direct sunlight and keep dry, with a shelf life of more than 1 year.